316L Stainless Steel Seamless Pipe offers excellent corrosion resistance, especially suitable for harsh environments containing chlorides (e.g. seawater, chemical plants).

Outer Diameter: 3.35 mm –101.6 mm

Wall Thickness: 0.5mm to 50mm (Sch5, Sch10, Sch40, Sch80, Sch160, etc.)

Length:3m, 6m,12m; Single Random, Double Random, Standard & Cut length

Size as per client request

316L stainless steel seamless pipe is a low carbon (C≤0.03%) austenitic stainless steel tube, manufactured through a seamless process to avoid weld defects, with 16-18% chromium, 10-14% nickel and 2-3% molybdenum, designed for high corrosion and high strength applications.

316L seamless pipe is the lower carbon version of 316 Stainless Steel. Its low-carbon design minimizes carbide precipitation during welding, ensuring weld integrity and avoiding intergranular corrosion. 316L steel contains 2-3% molybdenum, which significantly improves resistance to pitting and crevice corrosion in salt spray, acidic or chlorinated environments. With excellent mechanical strength and oxidation resistance, 316L stainless steel pipe is widely used in harsh industrial conditions to ensure reliable long-term equipment operation.

| Material | 316L,S31603,1.4404 | |

| Standard | ASTM A213, ASTM A249, ASTM A269, ASME SA213, ASME SA249, ASME SA269,etc | |

| Size | Outer Diameter | 6mm to 2500mm (0.25″ to 98″) |

| Wall Thickness | 0.5mm to 50mm (Sch5, Sch10, Sch40, Sch80, Sch160, etc.) | |

| Länge | 3m, 6m,12m; Single Random, Double Random, Standard & Cut length | |

| size as per client request | ||

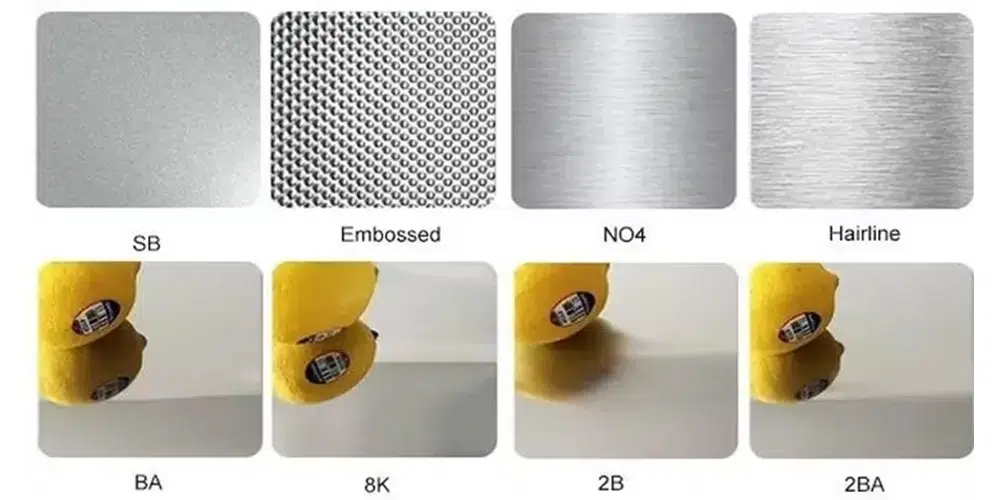

| Oberfläche | Polished, AP (Annealed & Pickled), BA (Bright & Annealed),etc BA,2B,No.1,2D,2B,8K,HL,etc | |

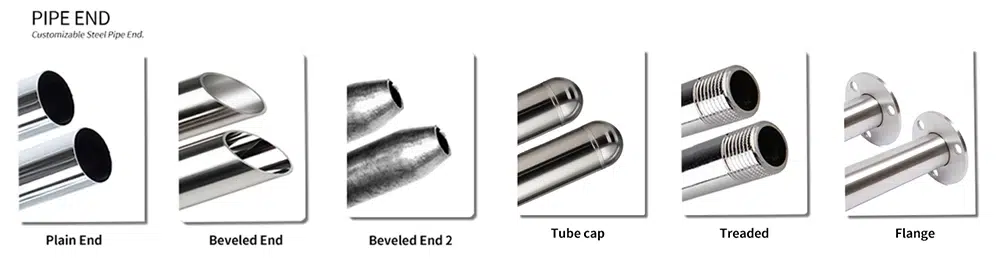

| End | Plain, Beveled,Treaded | |

1. Corrosion resistance

Enhanced corrosion resistance:

Low-carbon composition with molybdenum element synergizes to significantly outperform 304 series in resisting chloride ion corrosion.

2. Weldability

316L stainless steel with less than 0.03% carbon content to avoid carbide precipitation during welding, greatly reducing the risk of post-weld sensitization, which means that no additional annealing is required after the weld is formed to maintain corrosion resistance in the weld area.

In addition, 316L material has a bright surface finish after electrolytic polishing or pickling and passivation and is free from sources of contamination, fully meeting sanitary specifications for the cleanroom, food and pharmaceutical industries. Its excellent weld and cleaning characteristics make 316L pipes ideal for CIP/SIP systems and high-purity fluid transfer lines.

3. Safety and reliability:

Seamless structure avoids the risk of weld defects and is suitable for severe working conditions such as chemical and energy.

4. Variety of sizes:

OD 6.0-914.4 mm (larger sizes can be customized). Wall thickness range 0.3 to 50 mm (SCH5S-SCHXXS). Fulfills strict tolerances in accordance with ASME/ASTM A312 standards. Supports customized cutting.

To ensure stable quality, all of our pipes are made of high-quality raw materials from well-known steel mills such as Baosteel and TISCO, we strictly implement the whole process of quality control and provide detailed documents such as steel mill certificates (MTC), chemical compositions and mechanical property reports.

Customized Cutting and Chamfering:

316L Pipes can be cut to precise lengths according to drawings, and chamfered or screwed at both ends.

Surface Treatment:

mechanical polishing, electrolytic polishing and passivation are available to meet the high cleanliness requirements of the medical and food industries.

Inspection and Documentation:

Inspection services such as non-destructive testing, hardness testing, and third-party reports and quality certificates are available.

Package:

Experienced loading, unloading and packaging services, using standard seaworthy wooden crates or steel strapping packages to ensure tubes are shipped with protection.

Durch die vollständige Kontrolle über die Produkte können wir sicherstellen, dass unsere Kunden die besten Qualitätspreise und den besten Service erhalten. Kontaktieren Sie uns für ein kostenloses Angebot, JBLSTEEL wird die richtige Lösung für Ihr Projekt bieten.