Standard: ASTM A312

Common Use Grade: 304/304L;316/316L

Outer Diameter: 2 inch — 36 inch

Wall Thickness: SCH 5S — SCH XXS

Length: 6m,12m, and customized

JBLSTEEL supplies Stainless Steel Welded Pipe ASTM A312 in 304/304L, 316/316L with excellent resistance to high temperatures and corrosion.

Stainless Steel Welded Pipe ASTM A312 is a piping material designed for high-temperature and corrosive environments in a wide range of chemical, petrochemical, food processing, pharmaceutical and energy industries.ASTM A312 covers a wide range of stainless steel materials, including 304/304L, 316/316L, 310S, 321, 317L, and other grades, which have excellent resistance to high temperatures and corrosion, making it the preferred choice for industrial piping systems.

ASTM A312 is a standard specification developed by the American Society for Testing and Materials (ASTM) for seamless, welded, and heavy cold-worked austenitic stainless steel tubing. The standard is suitable for applications in high-temperature and generally corrosive environments in a wide range of chemical, petroleum, food processing, pharmaceutical, construction, and other industrial applications.

ASTM A312 stainless steel pipe is available in a wide range of sizes, from 1/8 inch to 30 inch outer diameters, and wall thicknesses from SCH 5S to SCH XXS.The surface finishes for these pipes include annealed, pickled, hand-polished, mechanically polished, and mirror-polished. In addition, the ASTM A312 standard covers chemical composition requirements for a wide range of grades, such as 304, 304L, 316, and 316L, each grade shall confirm the required chemical composition of C, Mn, P, S, Si, Cr and Cr, Ni, Mo, etc.

| Klasse | C | Si | Mn | P | S | Ni | Cr | Mo |

| 304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 8.0-11.0 | 18.0-20.0 | – |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-12.0 | 18.0-20.0 | – |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 |

Material Grade:

TP304/304L, TP316/316L (general corrosion resistant grades)

TP321, TP316Ti (high temperature creep resistance)

Others: TP309S, TP310S, Duplex (UNS S32205),etc

Size Range

Outer Diameter: 1/8”(10.3mm)– 36”(914mm)

Wall Thickness: SCH 5S — SCH XXS

Length: 20ft, 40ft, Single Random Length, Double Random Length and Customized

Tolerances

Outer Diameter: ±1.64mm for ≤NPS 1.5-inch pipe, ±1.5% for ≥NPS 2-inch pipe

Wall Thickness: Minimum wall thickness not less than 87.5% of nominal value.

Oberflächenbehandlung

2B bright-annealed, No.1 (hot-rolled), polished (mirror) or pickled finishes are available for corrosion resistance

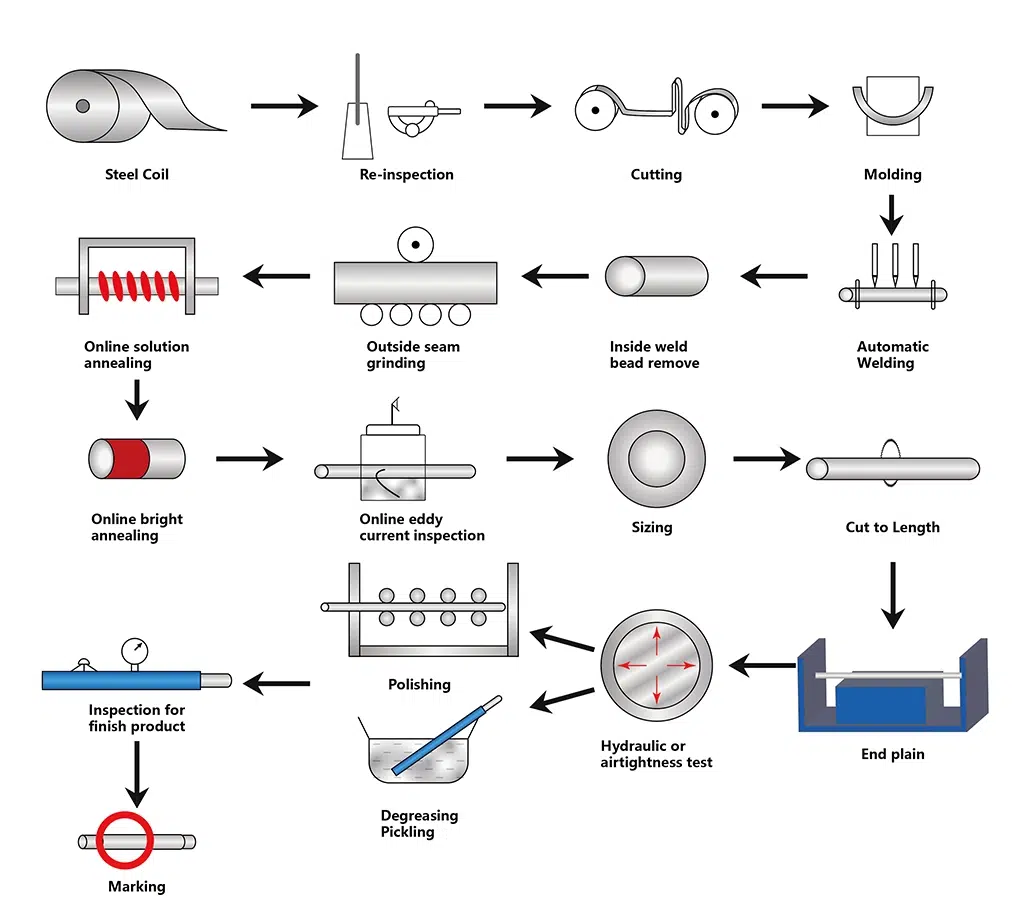

The production of ASTM A312 stainless steel pipe involves a variety of processes, such as seamless tubing, which is formed by extrusion or perforation, and welded pipe, which is made by welding stainless steel sheets or coils together.

ASTM A312 pipe covers the following manufacturing types (Including hot finished or cold finished):

1. Seamless Steel Pipe:

Manufactured by extrusion or piercing process.

2. Welded Steel Pipe:

Manufactured by welding stainless steel sheet or coil. Typically done by methods such as TIG (tungsten inert gas) welding, MIG (metal inert gas) welding or manual arc welding, and may require preheating and post-weld heat treatment to prevent sensitization and ensure corrosion resistance.

Requirements:

Mechanical testing including Tensile Test,Flatten Test and Non-destructive test.

Tensile Test

Take 304 stainless steel as an example, tensile strength ≥ 515 MPa, yield strength ≥ 205 MPa

Flatten Test or Hydrostatic Test

minimum pressure 17-19 MPa

Non-destructive Electric (NDE)

ultrasonic, eddy current testing instead of hydrostatic test

The ASTM A312 standard covers a wide range of stainless steel material grades,including:

304/304L:

General purpose austenitic stainless steels with good corrosion resistance and machinability, is the most versatile and most commonly used stainless steel, also known as “18/8” stainless steel, because the composition of the steel is 18% chromium and 8% nickel.

316/316L:

Molybdenum-bearing austenitic stainless steels with excellent corrosion resistance and high-temperature performance. Compared to 304, 316 resists chlorides and acids much better, making it ideal for harsh environments.

316Ti:

Titanium-containing austenitic stainless steel with excellent corrosion resistance and high-temperature properties.

321:

Austenitic stainless steel containing titanium or niobium, with high-temperature strength and good oxidation resistance.

347:

Austenitic stainless steel containing niobium, with excellent high temperature strength and resistance to intergranular corrosion.

1. Chemical Industry:

For the transportation of corrosive chemicals and to ensure that piping systems are safe and no leaks.

2. Food Processing:

Hygienic piping that meets strict hygiene standards and guarantees food safety.

3. Energy Industry:

Maintain stability in high-temperature and high-pressure environments, suitable for boilers and heat exchangers.

4. Pharmaceutical Industry:

Used in aseptic environments to ensure safe and reliable production processes.

ASTM A312 vs. ASTM A358:

1. ASTM A312

Covers seamless and welded (no filler metal) stainless steel tubes. Tubes are usually produced by extrusion (seamless) or automatic welding processes.

A312 welded pipe: mostly unit welded (high efficiency, single-sided welding), with large dimensional tolerances;

2. ASTM A358

Covers electrofusion welded (EFW) austenitic stainless steel pipes. Welding uses filler metals to increase strength and make it suitable for thicker walls.

A358 welded pipe: double-sided welding of plates, suitable for large diameter (≥ DN400), high-pressure scenarios.

Welded Pipe vs. Seamless Pipe:

Welded pipe strength is usually slightly lower than seamless pipe, but process advances have narrowed the gap, and performance in corrosive environments is comparable, and the variety and specifications of welded steel pipes are increasing.

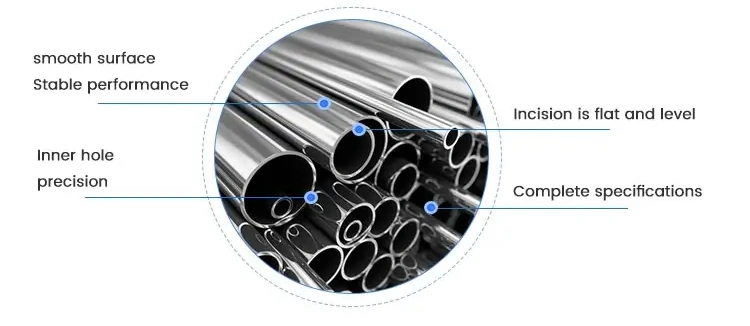

Premium Raw Material

We use premium materials (TP304/304L, TP316/316L) to ensure excellent corrosion resistance in harsh industrial environments. Source from top steel mills like TISCO and Baosteel, our pipes set the benchmark in quality and consistency.

Welded Quality

Automated welding processes (TIG, HF, HFI) with precise seam control ensure consistent high-quality welds.

Qualitätssicherung

Complete documentation (EN10204 3.1 material certificate, BL, packing list, invoice) and support for third-party inspections (SGS, BV, TUV) to ensure full traceability and quality assurance.

Customized Solutions

OEM/ODM capabilities, custom end preparations (beveling, threading), and export-ready packaging (bundles, wooden crates) are available; Available in sizes from ½″ up to 48″ (schedules Sch5S to Sch160), also can be customized.

Durch die vollständige Kontrolle über die Produkte können wir sicherstellen, dass unsere Kunden die besten Qualitätspreise und den besten Service erhalten. Kontaktieren Sie uns für ein kostenloses Angebot, JBLSTEEL wird die richtige Lösung für Ihr Projekt bieten.