- +86-15639045272

- wendy@jinblai.com

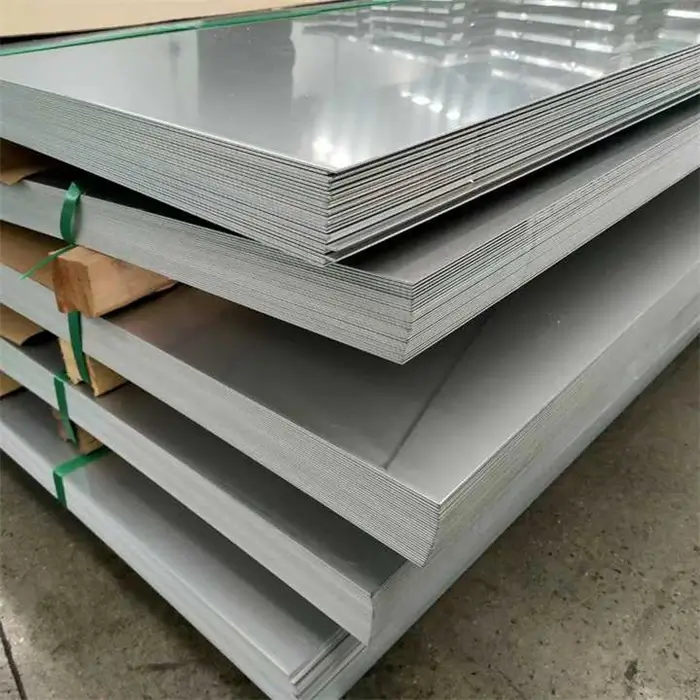

Stainless steel sheet is a flat‑rolled plate ≥ 0.5 mm thick, available in a variety of materials:

Thickness: 0.3mm–6mm

Width: 1000mm,1219mm,1250mm,1500mm,Customized Size

Stainless steel sheet is a thickness ≥ 0.5 mm flat rolled sheet, iron as a substrate, containing at least 10.5% chromium (the key to the formation of corrosion-resistant chromium oxide film), with addition of nickel, molybdenum and other elements to enhance specific properties (such as ductility, high temperature resistance), the common material 300 series austenitic and 400 series ferritic steel, the most widely used stainless steel grades 304/304L.

Corrosion resistance: Chromium forms a self-healing chromium oxide layer (passivation film) on the surface, resisting rust, corrosion resistance and high-temperature oxidation.

Thickness Range: Typically 0.3mm to 6mm, or ≤4.76mm, based on different base standards (thicker is categorized as stainless steel plate,thickness ≥ 0.188 inches/4.76mm for plate).

Material: 201/304/304L/316/316L/317/310S/430/410/409/2205/904L,etc

Thickness: 0.3mm–6mm

Width: 1000mm, 1219mm, 1250mm, 1500mm, 1800mm, 2000mm, Custom Size

Length: 2000mm, 2438mm, 2500mm, 3000mm, 4000mm, Custom Size

Surface: NO.1/2B/BA/HL/NO.4/6K/8K,Mirror/Satin,etc

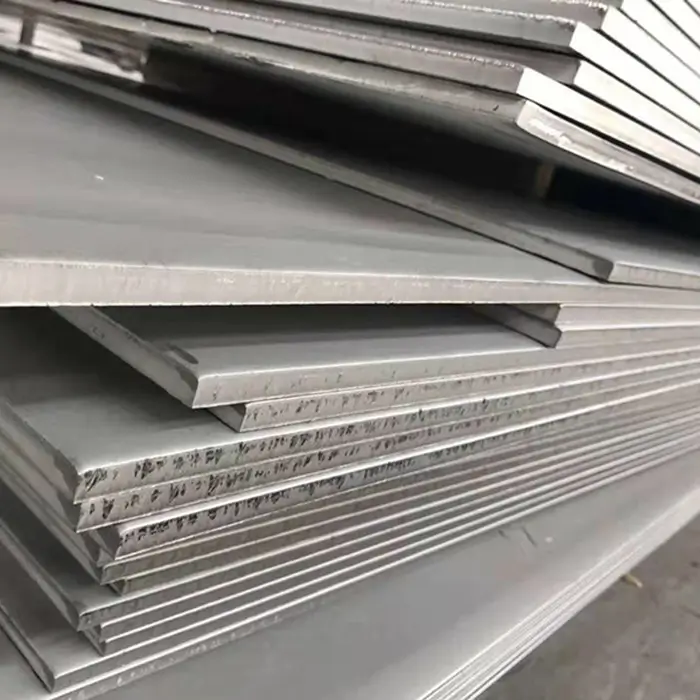

Technique: Hot‑rolled,Cold‑rolled

Processing Service: Bending, Welding, Decoiling, Punching, Cutting

Corrosion resistance

excellent resistance to water, atmosphere, and acidic environment, with longer service life than aluminium or ordinary steel.

300‑series grades (304, 316) resist chlorides, acids, and exterior weathering. Ferritic grades (430, 409) offer cost‑effective corrosion protection in mild environments

Mechanical properties

high yield strength and tensile strength, strong resistance to elastic deformation and plastic deformation, suitable for deep stamping and bending processing.

High Toughness and High Yield Point

with high yield point and tensile strength, stainless steel sheets perform resistant elastic deformation and plastic deformation from external force well.

Temperature adaptability

withstands temperature extremes from -200°C to 1000°C

Hygienic and easy-to-clean

non-porous surface prevents bacterial growth, widely used in food and medical equipment

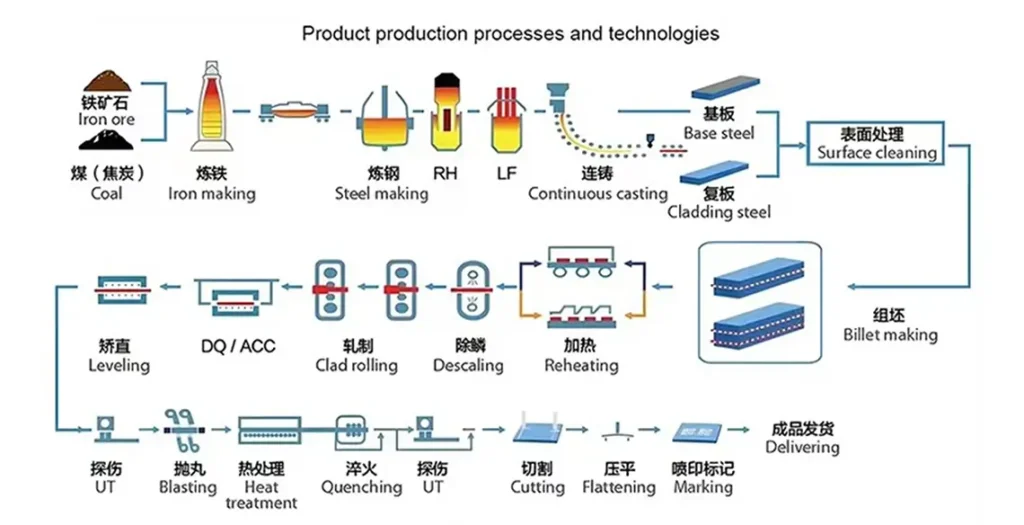

Rolling

hot or cold rolled billets are rolled into thin plates, cold rolled sheets are more accurate and have a smoother surface.

Our stainless steel sheets are made of high-purity stainless steel material and undergo strict quality control to ensure that each sheet possesses excellent corrosion resistance, strength and aesthetics. Whether it is standard size or special customization, we can meet your needs.

1. Advanced Rolling & Finishes

Hot‑rolled and cold‑rolled mills equipped with automated levelling produce smooth 2B, No. 4 brushed, BA mirror, and custom finishes with < 0.2 μm surface roughness.

2. Precision Dimensional Control

Sheet thickness tolerances ± 0.02 mm and flatness ≤ 2 mm/m, fulfill the requirements of precision machining and laser cutting.

3. Premium Raw Materials

Sourcing raw materials from famous steel mills and selecting high-purity stainless steel to ensure consistent chemical composition and grain structure, and strong corrosion resistance-—no sub‑standard coils.

4. Standardization

conforms to international standards such as ASTM, AISI, JIS, etc., with a common width of ≥610mm and a length of up to 6000mm.

5. Quality Assurance

Advanced production technology and testing equipment ensure a smooth surface and uniform thickness, which is in line with international standards.Material certificate is attached. 100% surface inspection, failure rate < 0.1%. Also support third-party inspection.

Yes, we offer customization services including different sizes, thicknesses and finishes to meet specific project needs.

While the initial cost may be higher than some materials, its durability and low maintenance costs make it more cost effective in the long term.

Stainless steel sheet is durable, corrosion resistant and easy to clean, making it ideal for use in areas such as construction, food processing and manufacturing.

Yes, they are highly resistant to weathering and corrosion, making them ideal for outdoor applications such as signage, railings and facade decoration.

Complete control over products allows us to ensure our customers receive the best quality prices and service. Contact us for a free quote,JBLSTEEL will provide the right solution for your project.

Σας καλωσορίζουμε θερμά να επισκεφθείτε την εταιρεία μας ανά πάσα στιγμή. Πιστεύω ότι η ποιότητα των προϊόντων μας, η επαγγελματική εξυπηρέτηση και η ανταγωνιστική τιμή θα σας ικανοποιήσουν. Ανυπομονούμε να συνεργαστούμε μαζί σας.

Πολιτική απορρήτου@ JBLSTAINLESS. Όλα τα δικαιώματα διατηρούνται από την Henan Jinbailai Industrial Co., Ltd.