316 Stainless Steel Tubing is an austenitic stainless steel pipe alloyed with 2-3% molybdenum, giving it exceptional corrosion resistance,significantly enhancing resistance to pitting and crevice corrosion.

316 Stainless Steel Tubing is a molybdenum-containing austenitic stainless steel tubing with excellent corrosion resistance and high-temperature strength, particularly suited to acidic, brine and chloride environments. Its chemical composition (containing 2-3% molybdenum) significantly enhances resistance to pitting and crevice corrosion, and excels above grade 304 stainless steel.

Widely trusted in industries like chemical processing, marine engineering, pharmaceuticals, and food production, this 316 molybdenum-enhanced tubing ensures safety, efficiency, and longevity. As a leading supplier, we provide high-quality, customizable 316 stainless steel tubing to meet your unique needs.

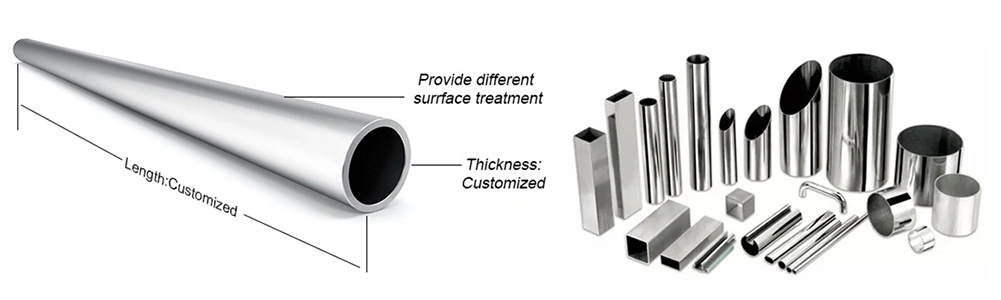

| Product Name | Stainless Steel Pipe/Tube | |||

| Technology | Hot Rolled,Cold Rolled | |||

| Material | 201,304,304L,310S,316,316L,321,430,430A,309S,2205,2507,430,410,440, 904L,ect, Or Customized | |||

| Thickness | 0.4-40 mm | |||

| Length | 1-12 m,cut to length | |||

| Outer Diameter(OD) | 10-2000mm | |||

| Standard | ASTM,JIS,GB,AISI,DIN,BS,EN | |||

| Certifications | ISO 9001,BV,SGS | |||

| Packing | Industry standard packaging or according to client’s requirement | |||

| Brand | TISCO,Baosteel,POSCO,LISCO,YUSCO,Ansteel, QPSS,JISCO,HXSCO, Chengde,Yongjin,Tsingshan,Shouyang | |||

| Delivery time | Fast delievery in 7 days,up to order quantity | |||

| Warehose Stcok | 5000 tons per month | |||

316 Stainless Steel Tube is a molybdenum-bearing austenitic chromium-nickel stainless steel with main components chromium, nickel and molybdenum, which has excellent corrosion resistance, high strength and toughness.Complies with ASTM A269/A312 and EN 10217-7 standard, backed by third-party inspection reports.

The Molybdenum-enhanced design offers excellent resistance to pitting and crevice corrosion, ideal for harsh environments.

Maintains stable performance under high temperatures and pressures, ensuring long-term reliability.

Polished or mirror finishes meet stringent requirements for food and pharmaceutical industries while enhancing decorative appeal.

Supports various specifications and processes, tailored solutions to meet your specific project requirements.

Element | Min | Max |

C | – | 0.08 |

Mn | – | 2 |

Ni | 10 | 14 |

Cr | 16 | 18 |

Mo | 2 | 3 |

S | – | 0.03 |

Si | – | 1 |

P | – | 0.045 |

316 stainless steel pipe has high strength,good ductility, and excellent welding performance, suitable for various complex processing needs. It has strong fatigue resistance and can withstand long-term mechanical stress without breaking or deformation.

| Temper | Annealed | Cold worked (approx. 20%) | ||

| Tensile,Rm | 75 | ksi (min) | 102-131 | ksi (min) |

| Tensile,Rm | 515 | MPa (min) | 700-900 | MPa (min) |

| R.p. 0.2% Yield | 30 | ksi (min) | 73-102 | ksi (min) |

| R.p. 0.2% Yield | 205 | MPa (min) | 500-700 | MPa (min) |

| Elongation (2” or 4D gl) | 35 | % (min) | 40 | % (min) |

316 stainless steel tubing resists chloride corrosion in seawater desalination systems, extending pipeline lifespan.

used in aseptic delivery systems to ensure safe and pollution-free drug production.

Acid and alkali resistance supports complex chemical transport, boosting production efficiency.

Heat exchangers and boiler systems requiring high-temperature stability.

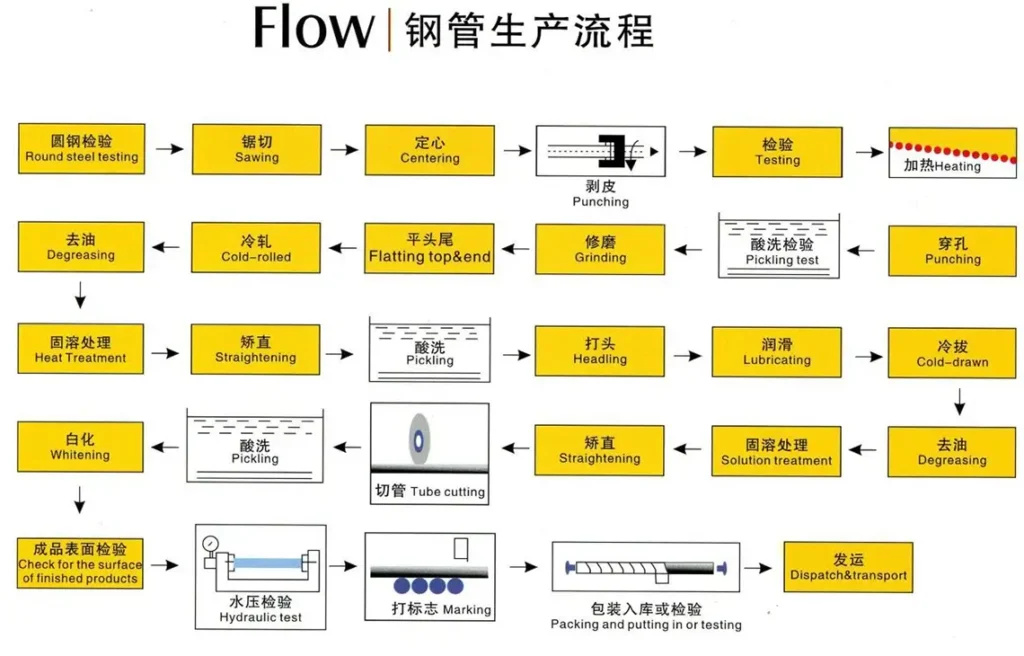

The production process of 316 stainless steel tubes includes melt welding, cold drawing, heat treatment and surface treatment to ensure high surface finish, precise dimensions,and can meet the needs of different specifications and shapes.

Seamless tubes are suitable for high pressure applications, while welded tubes are more economical. Surface finishes can be selected according to your application – polished tubes for hygienic applications and pickled tubes for industrial applications.

To prolong the service life, 316 stainless steel pipes need to be cleaned regularly, avoiding contact with strong acid or alkali environments, to prevent static reactions and oxidative corrosion. In addition, the appropriate welding method should be selected during the welding process to reduce cracking and oxidation problems.

Complete control over products allows us to ensure our customers receive the best quality prices and service. Contact us for a free quote,JBLSTEEL will provide the right solution for your project.

Le invitamos a visitar nuestra empresa en cualquier momento. Creo que la calidad de nuestros productos, el servicio profesional y el precio competitivo le satisfarán. Esperamos cooperar con usted.

Política de privacidad@ JBLSTAINLESS. Todos los derechos reservados por Henan Jinbailai Industrial Co, Ltd.