Stainless steel welded tube, with cost-effectiveness, flexibility, and durability, is the ideal choice for industries such as construction, chemicals, and food processing.

Welcome to JBLSTEEL, your trusted partner for top-quality stainless steel welded tube.Stainless steel welded tubes, with cost-effectiveness, flexibility, and durability, are the ideal choice for industries such as construction, chemicals, and food processing. As a leading supplier and manufacturer in China, we are committed to providing you with high-quality, customized stainless steel welded tubes to ensure the success of your projects.

Whether your project is small, or large,our stainless steel welded tubes are designed to meet all your needs.From the construction, and food processing, to industrial applications,our welded pipes offer flexibility, durability, and sustainability solutions for any application.Explore our range of welded stainless steel pipe today and elevate your working production with the best solutions for your project!

Whether for industry, construction, machinery manufacturing and other fields,our welded tubes offer the perfect solution for your specific project, providing excellent corrosion resistance, high strength and processing performance.

El acero inoxidable austenítico es uno de los tipos de acero inoxidable más utilizados, conocido por su excelente resistencia a la corrosión, conformabilidad, soldabilidad y propiedades no magnéticas. La composición principal consiste en al menos 10,5% de cromo y 8% de níquel, con otros elementos como el nitrógeno y el carbono también presentes.

Adecuado para la industria alimentaria, química y la decoración arquitectónica.

El acero inoxidable ferrítico es un tipo de aleación de acero inoxidable, conocido por su resistencia a la corrosión, sus propiedades magnéticas y su rentabilidad. Pertenece a la serie 400 de aceros inoxidables y se caracteriza por su estructura cristalina cúbica centrada en el cuerpo (BCC), que le confiere propiedades magnéticas diferentes de los aceros inoxidables austeníticos.

Adecuado para utensilios de cocina y sistemas de escape de automóviles.

El acero inoxidable martensítico, conocido por su gran solidez, resistencia al desgaste y resistencia moderada a la corrosión, es magnético debido a su estructura cristalina tetragonal centrada en el cuerpo (BCT) y se compone principalmente de cromo (12-17%) y carbono (hasta 1,2%), con un contenido mínimo de níquel. La ausencia de níquel hace que el acero inoxidable martensítico sea más rentable que el acero inoxidable austenítico.

Los aceros inoxidables dúplex son una familia de aceros inoxidables con una microestructura mixta de fases austenita y ferrita en proporciones aproximadamente iguales. Ofrecen una combinación de propiedades de los aceros inoxidables austeníticos y ferríticos, una mayor resistencia a la corrosión y una mayor solidez. Los aceros inoxidables dúplex son magnéticos y muchos de ellos son aproximadamente el doble de resistentes que los austeníticos y ferríticos.

Commonly used in food machinery and medical equipment.

Low carbon version, reducing the risk of sensitization during welding.

Better corrosion resistance in chloride environments

Low carbon version, used in applications requiring high corrosion resistance.

Used in automotive trim and appliances.

Used in automotive exhaust systems.

Used in knives and medical devices.

High hardness, used for cutting tools and other high strength applications.

2205 (022Cr22Ni5Mo3N)

Used in the petroleum and chemical industries, with high strength and corrosion resistance

Better overall performance, suitable for moderately corrosive environments

Stainless steel welded tube is a steel pipe made by welding steel plates or strips after rolling into shape, with a variety of categories and shapes.Stainless steel welded pipes can be divided into round,rectangular and special-shaped tubes according to the cross-section shape,including rhombic, hexagonal, octagonal,etc. The shaped pipes are mainly used for special mechanical parts and tools.

Stainless steel welded pipes are classified into different types based on the welding method and the shape of the weld. Here are two common types of stainless steel welded pipes:Straight Seam stainless steel welded pipes and spiral stainless steel welded pipes(SSAW).

Straight Seam stainless steel welded pipes can be divided into:ERW and LSAW

ERW

LSAW

SSAW

Grado:

304/L/H/LN;316/L/H/LN/Ti;321/H;317/L/LN;347/H;310S/H;S31803;S32205;S32750;S32760;

N08904(904L);N02200;N02201;N04400;N06600;N06690;N06625;

N06985(G3);N08028;N08800;N08810;N08811;N08825

Estándar:GB;ASTM;ASME;EN;DIN;JIS;GOST

Forms:Round/Square/Elliptical/Triangular/Groove tube,etc

Tubing Schedule:SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

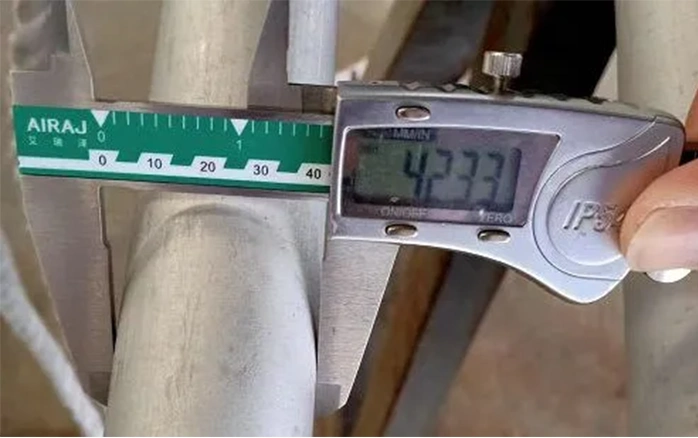

Outer Diameter: 12-3000mm

Espesor de pared: 0.4-100mm

Longitud: up to 6m,custom cut length

Tratamiento de la superficie: Pickled, Polished, Mirror Finish, Sandblasting,or as required

JBLSTEEL Welded Tubes offer a highly versatile solution for all your application needs.Whether from industry, construction,and machinery manufacturing, we provide pipe options that cater to various requirements, ensuring optimal performance and longevity in every project.Stainless steel welded tubes are essential components in a wide range of industries due to excellent corrosion resistance, high strength and processing performance.

Stainless steel welded tubes are formed by welding stainless steel plates or strips, offering excellent corrosion resistance, strength, surface finish, flexibility, and durability,suitable for medium to low-pressure and decorative applications, such as pressure vessels, heat exchangers,and piping systems, etc.

Used in railings and support structures for high-end buildings, offering aesthetics and durability

Sanitary piping to ensure food production safety.

Economical and efficient for low-pressure fluid transport.

Exhaust Systems

Personalización flexible

Supports various materials, sizes, and surface treatments to meet diverse project needs.

Excelente resistencia a la corrosión

Made from high-quality stainless steel with specially treated welds to ensure long-term corrosion resistance.

High Surface Finish

Available with polished or mirror finishes to meet decorative and sanitary requirements.

Welded Seam Quality

Our stainless steel welded tubes are produced using advanced high-frequency welding technology and a rigorous quality control system, ensuring smooth and solid welds, pure materials.

Quality Control

Every batch undergoes strict testing, including material analysis, weld strength testing, IGC testing, radiographic testing,and surface quality inspection,micro or macro test, flattening test and flaring test and finalize by third parties,to ensure defect-free delivery.

International Standards

Our stainless steel welded tubes have obtained multiple international certifications, including ISO 9001, ASTM A312/A778 and EN 10217-7 standard certification,guarantee that our pipes meet the highest global standards in material, craftsmanship, and performance, fulfilling the stringent requirements of various countries and industries..

Precios competitivos

We offer highly competitive pricing while ensuring product quality. By optimizing production processes and supply chain management, we provide you with high-value products without compromising on quality.

On-time Delivery

With efficient production capabilities and a global logistics network, we promise on-time delivery. Whether it’s a small batch or a large order, we can handle it flexibly to ensure your project stays on schedule.

Comprehensive Services

Our professional team offers comprehensive services from selection consultation to after-sales support. Whether you have technical questions or customization needs, we respond quickly to ensure your requirements are met.

El control total sobre los productos nos permite garantizar a nuestros clientes la mejor calidad, precios y servicio. Póngase en contacto con nosotros para un presupuesto gratuito, JBLSTEEL proporcionará la solución adecuada para su proyecto.