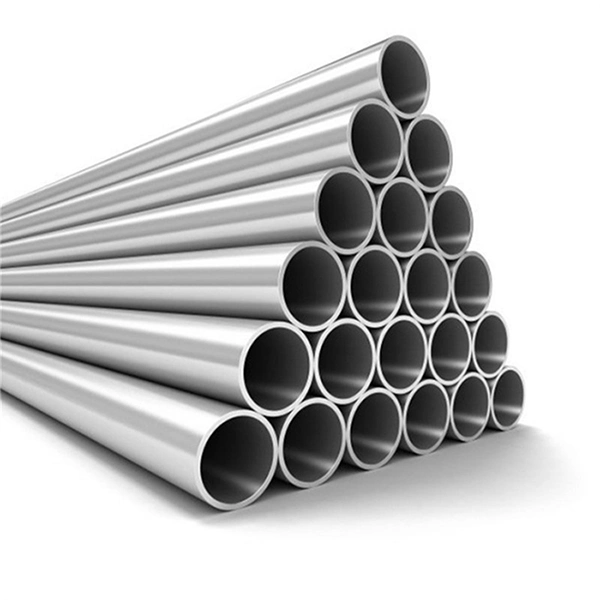

316 Stainless Steel Seamless Pipe is a high-quality tubing made primarily from the elements of iron, chromium, nickel and molybdenum, is an ideal choice for superior performance and a wide range of applications. The addition of molybdenum significantly enhances corrosion resistance, especially in chlorinated and acidic environments.

316 SS Pipe Form

316 stainless steel is an austenitic stainless steel containing 16-18% chromium, 10-14% nickel and 2-3% molybdenum. The addition of molybdenum significantly improves corrosion resistance, especially in chlorinated and acidic environments. Compared to grade 304, 316 has greater corrosion resistance in chlorinated and acidic media, and is suitable for corrosive environments.

316 Stainless Steel Seamless Pipe is hot rolled from solid billets and is not welded.This no-seams design eliminates weak points and provides consistent mechanical strength and higher pressure ratings. Seamless pipes offer the highest strength, pressure capacity and corrosion resistance, and are well suited for use in critical industries such as oil and gas, chemical, and power.

1. Superior Corrosion Resistance

The addition of molybdenum can effectively prevent pitting and crevice corrosion, and can work stably for a long term in seawater, salt spray, sulfuric acid and other strong corrosive media, surpassing that of 304 stainless steel.

2. High-Temperature Strength

316 retains excellent mechanical strength at elevated temperatures, with better creep resistance than 304. This stability under heat makes it suitable for heat exchangers, boilers and other high-temperature system.

Maintains structural stability at elevated temperatures, making it suitable for high-temperature processes.

3. High Strength

The seamless design allows it to withstand higher pressures and mechanical stresses, ensuring greater strength and pressure resistance, reducing the risk of leakage and ensuring system safety.

4. Hygienic Aesthetics and Easy Maintenance

The smooth surface has an attractive appearance and is easy to clean, making it suitable for food and medical industries, while the smooth interior reduces dirt accumulation and lowers maintenance costs.

Standard: ASTM A312,ASTM A269,EN ISO 3651-2,etc;

Outer Diameter: 3-630 mm;

Wall thickness: 0.5-50 mm(SCH10-XXS);

Length:1-12 m,can be customized;

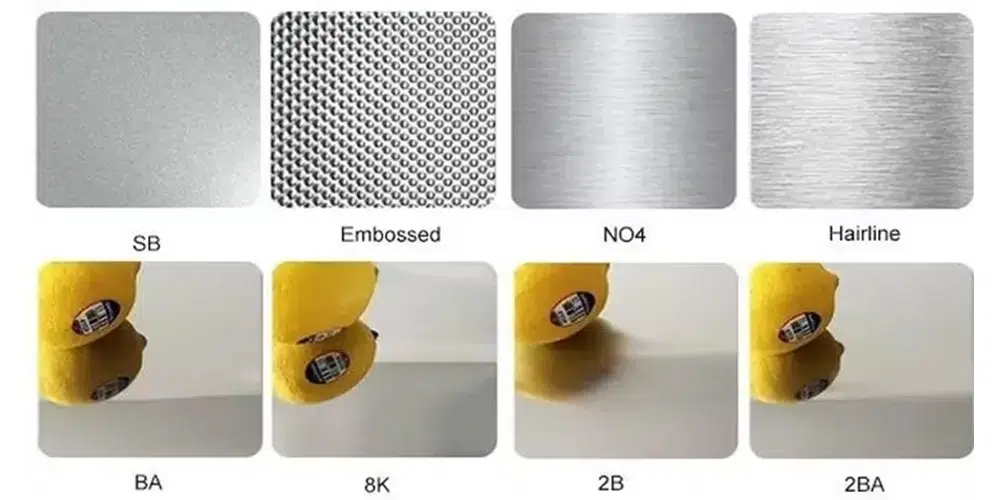

Surface Finish: BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D;

Type: Seamless;

Technique: Hot Rolled/Cold Rolled;

Surface: Polishing,annealing,pickling,bright

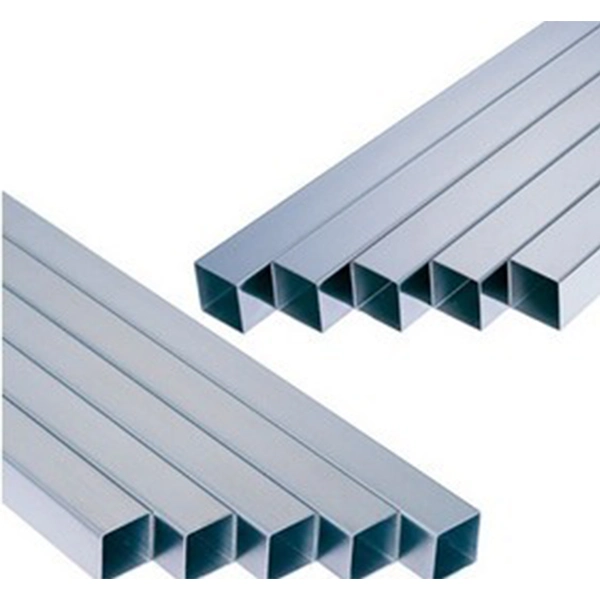

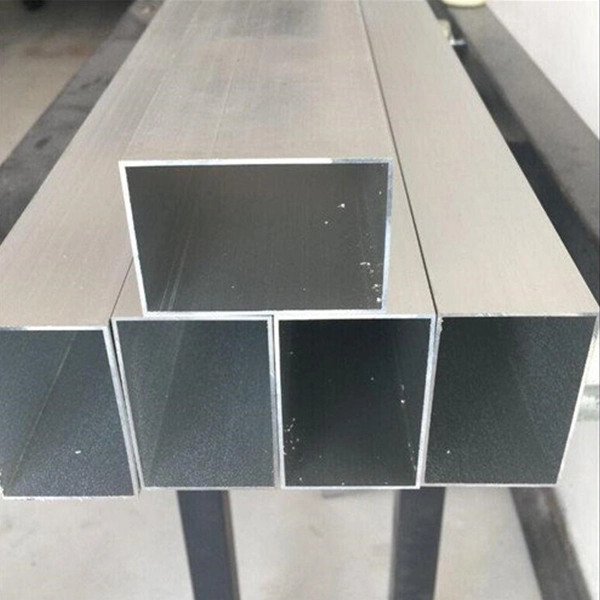

Shape:Round.Square.Rectangle,etc

Stainless Steel Round Tube Pipe | |

Wall thickness | 0.5mm-20mm |

Outer diameter | 10mm-2000mm |

Stainless Steel Square Tube Pipe | |

Wall thickness | 0.5mm-20mm |

Outer diameter | 4mm*4mm-800mm*800mm |

Stainless Steel Rectangular Tube Pipe | |

Wall thickness | 0.5mm-20mm |

Outer diameter | 1mm-150mm |

| GRADE | C | MN | SI | P | S | CR | MO | NI | N | |

| 316 | Min |

– |

– |

– |

0 |

– |

16.0 |

2.00 |

10.0 |

– |

|

Max |

0.08 |

2.0 |

0.75 |

0.045 |

0.03 |

18.0 |

3.00 |

14.0 |

0.10 |

| Grade | UNS | Specification |

Minimum Yield Strength at 0.2 % Offset ksi |

Minimum Tensile Strength ksi |

Elongation in 2 in. (50.8mm)% min |

| Strain-Hardened 316/316L Stainless Steel Seamless Pipe | |||||

| 316/316L |

S31600/ S31603 |

ASTM A269 ASTM A262 EN ISO 3651-2 |

75 | 100 | 20 |

| Annealed 316/316L Seamless Pipe | |||||

| 316/316L |

S31600/ S31603 |

ASTM A269 ASTM A262 EN ISO 3651-2 |

40 | 70 | 35 |

| GRADE | DENSITY (KG/M3) | ELASTIC MODULUS (GPA) | MEAN CO-EFF OF THERMAL EXPANSION (ΜM/M/°C) | THERMAL CONDUCTIVITY (W/M.K) | SPECIFIC HEAT 0-100°C (J/KG.K) | ELEC RESISTIVITY (NΩ.M) | |||

| 0-100°C | 0-315°C | 0-538°C | AT 100°C | AT 500°C | |||||

| 316 | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 74 |

GRADE | UNS | OLD BRITISH | EURONORM | SWEDISH | JAPANESE | ||

BS | EN | NO | NAME | ||||

316 | S31600 | 316S31 | 58H, 58J | 1.4401 | X5CrNiMo17-12-2 | 2347 | SUS 316 |

All seamless pipes are made from certified 316 stainless steel supplied by China’s leading mills (TISCO, Baosteel). These top-tier steels have fully controlled chemistry and consistently high quality, ensuring our pipes meet stringent specifications.

We enforce strict dimensional control (OD, wall thickness, roundness) to ensure accuracy. Our 316 seamless pipes are available in standard sizes from ½″ to 18″ NB and wall schedules Sch5S–Sch160,with tight tolerances for critical applications. Custom lengths and special end finishes (plain, beveled, threaded) are also available.

We also cut pipes to exact lengths (standard 6m or custom sizes 5.8m, 11.8m, etc.) and offer special end machining (threading, flanges) to fit your needs.

316 SS Pipe Application

316 SS seamless pipes are widely used in critical systems in various industries. The acid and chloride resistance of 316 is crucial in chemical processes, while its durability in marine environments makes it an ideal material for offshore applications.

Custom Size&Fabrication

We cut pipes to exact lengths and offer special end machining (threading, flanges) to fit your needs.We can also adjust outer diameter or modify as OEM parts.

Third-Party Inspection

We carry out strict quality tests like dimensional inspection, composition test, hardness test, etc. before shipment.We also support Third-Party inspections (SGS, Bureau Veritas, TUV, etc.),our quality assurance team fully cooperates with inspectors and can provide pre-shipment reports.

Standard Export Seaworthy Package

Pipes are fitted with plastic dust caps and waterproof packaging, secured by steel straps or packed on wooden pallets to ensure safe transportation over long distances.

Complete control over products allows us to ensure our customers receive the best quality prices and service. Contact us for a free quote,JBLSTEEL will provide the right solution for your project.

Nous vous invitons chaleureusement à visiter notre entreprise à tout moment. Je suis convaincu que la qualité de nos produits, notre service professionnel et nos prix compétitifs vous satisferont. Nous nous réjouissons de coopérer avec vous.

Politique de confidentialité@ JBLSTAINLESS. Tous droits réservés par Henan Jinbailai Industrial Co, Ltd.