Stainless steel is a versatile material used in countless industries, but not all stainless steel is created equal.Both 304 (SS 304) and 316 (SS 316) belong to the austenitic stainless steel family,are widely utilized materials in various industries due to their excellent mechanical properties and corrosion resistance, sharing similar compositions, primarily consisting of chromium and nickel.

Two of the most popular grades, SS 304 and SS 316[1], are often confused due to their similar appearance. However, their properties and applications differ significantly.316 steel contains molybdenum, which enhances its resistance to corrosion in challenging environments, particularly those involving chlorides such as seawater,making 316 a preferred choice for applications requiring superior corrosion resistance, while grade 304 is often selected for its cost-effectiveness and sufficient performance in less demanding conditions.

Why Identifying SS 304 and SS 316 Matters

Identifying the correct stainless steel grade is essential for ensuring optimal material performance across diverse applications, ranging from aerospace and medical equipment to food processing and marine environments.

Choosing the wrong grade of stainless steel can lead to costly mistakes, such as premature corrosion, structural failures, or non-compliance with industry standards.

For example:

- Using 304 baja tahan karat[2] in a marine environment could result in rapid corrosion due to exposure to saltwater.

- Stainless steel grade 316[3] in a low-corrosion, cost-sensitive application might unnecessarily increase your budget.

By understanding how to identify these grades, you can ensure optimal performance, cost-efficiency, and longevity for your project.

Key Differences Between SS 304 and SS 316

| Properti | Grade 304 | Grade 316 |

| Komposisi | 18% chromium, 8% nickel | 16% chromium, 10% nickel, 2% molybdenum |

| Ketahanan Korosi | Good resistance to rust and staining | Excellent resistance, especially to chlorides and acids |

| Strength | Moderate strength | Higher strength due to molybdenum |

| Biaya | More cost-effective | Slightly more expensive |

| Applications | General-purpose use | Harsh environments, marine, medical |

Chemical Composition

Stainless steel grades 304 and 316, both belonging to the austenitic family, have similar foundational elements such as chromium and nickel. However, the most significant difference is the addition of molybdenum in 316 stainless steel, typically comprising 2-3%, significantly enhances the corrosion resistance of 316, particularly in environments rich in chlorides, such as seawater.

The typical chemical composition of 304 stainless steel includes approximately 18% chromium and 8% nickel, while 316 stainless steel generally contains similar amounts of chromium and nickel but benefits from the added molybdenum for improved performance in corrosive environments.

| Kelas | C | Si | Mn | P | S | N | Cr | Ni | Mo |

| 304 | 0.07 | 1.00 | 2.00 | 0.045 | 0.015 | 0.10 | 17.5-19.5 | 8.0-10.5 | - |

| 316 | 0.07 | 1.00 | 2.00 | 0.045 | 0.015 | 0.10 | 16.5-18.5 | 10.0-13.0 | 2.0-2.5 |

Ketahanan Korosi

Stainless steel as a family of metals is very corrosion resistant, but with the addition of molybdenum into 316 increases the grades ability to withstand harsh environments. Often referred to as marine grade, 316 is suitable for use in environments that are more aggressive than ambient although care should still be taken to clean the metal regularly to prolong its service life.

Sifat Fisik

The physical properties of stainless steel, including density and thermal conductivity, also play a crucial role in material selection. The density of 304 stainless steel is approximately 0.29 lb/in³, which is significantly higher than that of aluminum alloys, therefore aiding in distinguishing between different materials.

For applications that required higher durability and wear resistance , the superior corrosion resistance and physical properties of SS 316 make it a preferred choice in harsh environments.

Cara Mengidentifikasi SS 304 dan SS 316

Identifying stainless steel grades, particularly SS 304 and SS 316, is crucial for ensuring the proper material is used in various applications. Here are some reliable methods to distinguish between SS 304 and SS 316:

Chemical Tests

Chemical tests can also help identify specific stainless steel grades. One effective method involves dissolving a small sample in a mixture of nitric and hydrochloric acid, then adding a nickel reagent. The presence of nickel is confirmed if a red fluffy substance forms, which is particularly relevant for identifying 304 material due to its significant nickel content.

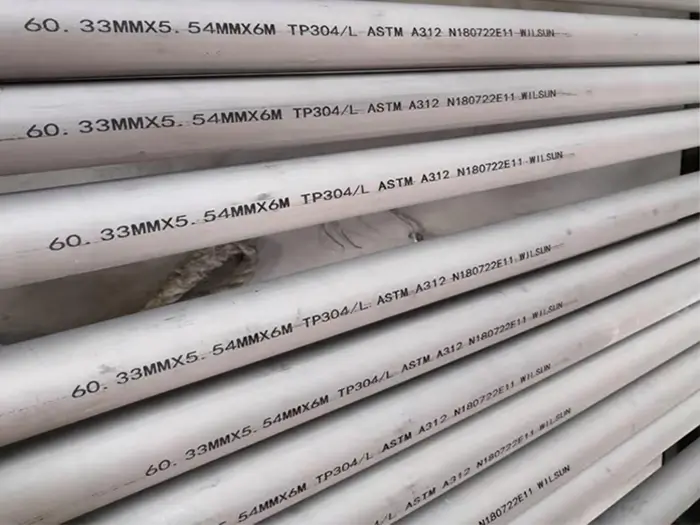

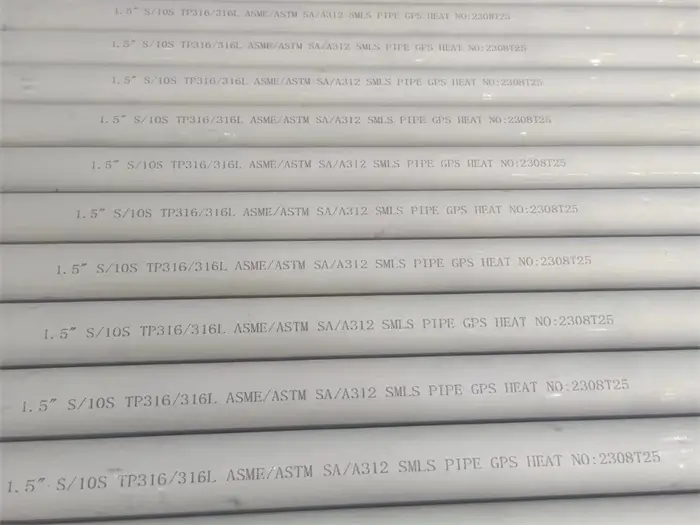

Material Marking

Many stainless steel products are stamped or engraved with their grade (e.g., “304” or “316”). Check the surface of the material for these markings, especially on pipes, sheets, or fittings.304 and 316 stainless steel will have different material markings, such as SUS304 or SUS316.

Surface Color Identification

The most basic approach to stainless steel identification is visual inspection. 304 stainless steel typically presents a bright silvery gray appearance, while 316 may exhibit a slightly different sheen due to its molybdenum content, which enhances corrosion resistance.

Magnetic Testing

Magnetic testing is an effective preliminary method, but with some limitations,useful in differentiating austenitic grades like SS 304 from ferritic or martensitic grades. SS 304 is generally non-magnetic or only weakly magnetic; if a magnet does not stick to the sample, it may indicate the material is SS 304 or another non-magnetic grade.

While both 304 and 316 are generally non-magnetic in annealed state, cold working can make them slightly magnetic. This makes the magnet test less reliable for definitive identification.

Aplikasi

304 Baja Tahan Karat

The high concentration of Chromium gives alloy 304 excellent corrosion resistance,making it commonly used in kitchen equipment, indoor electrical enclosures, and water piping.304 stainless steel widely used in following applications

- In making kitchen appliances like refrigerators and dishwashers

- Used to make heat exchangers

- Used in commercial food processing equipment and kitchen fittings like sinks and splash backs

- Used to make saucepans, cutlery and flatware

- Architectural paneling

- In making nuts, bolts, screws and nuts

- Used in making brewery, food, and pharmaceutical production equipment.

316 Baja Tahan Karat

316 Stainless steel has better corrosion resistance than Stainless steel and often exhibits better strength at high temperatures,often found in chemical piping, pharmaceutical equipment, marine environments, and food processing facilities with harsher chemicals.

- Making food, chemical and petrol production and processing equipment

- Construction of laboratory benches and equipment

- Architectural panelling in the coastal region

- Boat fitting

- Mining screens

- Kitchenware, sanitaryware and troughs

- Tubing

- Medical implants

Biaya

The increase of nickel content and the addition of molybdenum in 316 makes it more expensive than 304. On average, the price of 316 stainless steel 40% higher than the price of Grade 304.

316 vs 304 Stainless Steel: Which is Better?

If you require superior corrosion resistance, particularly in harsh environments, 316 is the better choice. If corrosion resistance is not a critical factor, 304 is a practical and cost-effective option.

316 stainless steel is more resistant than 304 to salt and other corrosives. So, if you are manufacturing a product that will often face exposure to chemicals or a marine environment, 316 is the better choice.

If you are manufacturing a product that does not need strong corrosion resistance, 304 is a practical and economical choice. For many applications, 304 and 316 are actually interchangeable.

Disclaimer: Many things here represent our opinion. We can therefore never claim to be correct or complete. And never base a business decision solely on the news you receive from us.

[1]Understanding the differences can help you choose the right stainless steel for your project, ensuring durability and performance.

[2]Exploring the properties of 304 stainless steel can guide you in selecting materials for various applications, enhancing your project’s success.

[3]Learning about the benefits of grade 316 can help you make informed decisions for corrosion resistance and strength in your projects.