347 stainless steel seamless pipe is a niobium (Nb)-stabilized austenitic stainless steel optimized for high-temperature, long-term service environments.

Excellent resistance to intergranular corrosion

Superior high-temperature properties

Good machinability and weldability

347 stainless steel is a grade developed by adding the stabilizing element niobium to chromium-nickel austenitic stainless steel. Its seamless tubes are manufactured through processes such as hot rolling, hot extrusion, cold drawing, or cold rolling, resulting in steel pipes with no weld seams on either the inner or outer walls. This production method endows the pipes with higher pressure-bearing capacity, more uniform microstructure, and excellent dimensional accuracy.

347 stainless steel seamless pipe is a niobium-stabilized austenitic stainless steel pipe containing 0.32-1% niobium to prevent high-temperature sensitization, providing excellent high-temperature strength and corrosion resistance, suitable for conditions exceeding 425°C.

Standard: ASTM A269, ASTM A213, ASTM A312

Wall Thickness: Schedule 10 To Schedule 160 (3 mm to 100 mm Thickness)

Outer Diameter Size: 0.5” NB – 16” NB

Length: 0.1m – 12.5m,Single Random Length, Double Random Length And Customize Size

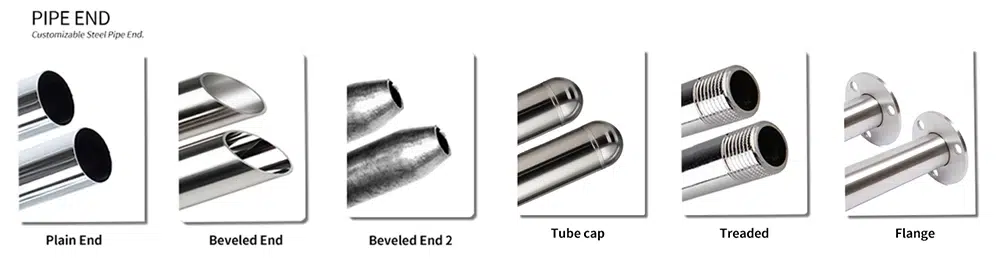

Pipe Ends: Plain / Beveled / Treaded

Value Added Service: Polishing, Beveling, Honing/Turning, Heat Treatment / Annealed / Bright Annealed

347 stainless steel is an austenitic stainless steel containing niobium and tantalum to prevent the formation of chromium carbides, offering excellent resistance to intergranular corrosion and is suitable for high-temperature environments. Its corrosion resistance is superior to that of 321 stainless steel, making it suitable for both high-temperature and low-temperature environments, with good corrosion resistance and heat resistance.

Based on carbon content, 347 stainless steel is primarily divided into two grades:

347 Stainless Steel (UNS S34700): Its carbon content is typically below 0.08%, making it suitable for most high-temperature and corrosion-resistant applications.

347H Stainless Steel (UNS S34709): the high-carbon version of 347, with carbon content typically between 0.04% and 0.10%. The higher carbon content, combined with niobium, significantly enhances the material’s high-temperature strength and creep resistance, making it more suitable for long-term use in pressurized environments at ultra-high temperatures (typically above 538°C).

The difference in carbon content makes 347H significantly superior to 347 in terms of allowable stress and creep rupture strength at temperatures exceeding 538°C (1000°F), making it one of the preferred materials for high-temperature applications in the ASME Boiler and Pressure Vessel Code.

Unlike 304 grade steel, 347 stainless steel has better creep strength and rapture properties. It also works best in extreme heat conditions and has an excellent high pressure bearing capacity. It has better toughness along with good overall strength.

1. Nb-Stabilized Structure: Suppressing Intergranular Corrosion

Compared to 304H and 321, 347 stainless steel incorporates niobium (Nb) to preferentially form stable carbides with carbon:

2. 347 Seamless Steel Pipe: Suitable for High-Temperature and High-Pressure Conditions

3. High-Temperature Strength

347 stainless steel exhibits greater stability in the following:

4.Excellent Machinability and Weldability

Stainless steel 347 exhibits excellent cold and hot workability. Its hot processing (such as forging and hot rolling) typically involves temperatures ranging from 1150 to 1250°C.

Due to the stabilizing effect of niobium, welded joints are less susceptible to intergranular corrosion, thus post-weld heat treatment is generally unnecessary.

| Standard | Element | C | Cr | Mn | Ni | P | S | Si | Cb/Ta |

|---|---|---|---|---|---|---|---|---|---|

| ASTM A213 /ASTM A312 | 347 | 0.08 max | min: 17.0 max: 20.0 | 2.0 max | min: 9.0 max: 13.0 | 0.04 max | 0.30 max | 0.75 max | min:10x C max: 1.0 |

| 347H | min: 0.04 max: 0.10 | min: 17.0 max: 20.0 | 2.0 max | min: 9.0 max: 13.0 | 0.03 max | 0.30 max | 0.75 max | min:10x C max: 1.0 |

| Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% ksi offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 347/347H | 75 (515) | 30 (205) | 40 | 201 | 95 |

With its unique performance characteristics, 347 stainless steel seamless pipe plays an indispensable role across multiple industries.

Petroleum & Chemical Plants

347 stainless steel pipes deliver stable post-weld performance and intergranular corrosion resistance, minimizing unplanned downtime

Power & Energy Engineering

Maintaining long-term high-temperature strength stability, 347 steel pipes offer a design life exceeding 20 years

Industrial Furnaces & Heat Treatment Equipment

347 stainless steel resists thermal fatigue, making it ideal for applications with frequent start-stop cycles.

Complete control over products allows us to ensure our customers receive the best quality prices and service. Contact us for a free quote,JBLSTEEL will provide the right solution for your project.